Understanding Polini Thor 250 CDI Problems

Polini Thor 250 CDI problems can significantly impact the reliability and performance of your paramotor. The CDI (Capacitor Discharge Ignition) system is crucial for ensuring smooth engine starts and efficient operation, making it an integral component of the Polini Thor 250 setup. A well-functioning CDI is essential for achieving the optimal flying experience and maintaining the dependability of your paramotor.

Despite its importance, the Polini Thor 250 CDI can encounter various issues that may disrupt your flying sessions. Common problems associated with the Polini Thor 250 CDI often include ignition failures, inconsistent power delivery, or difficulty starting the engine. By familiarizing yourself with these potential challenges and their solutions, you can effectively troubleshoot issues and keep your engine running at peak performance. This proactive approach allows you to focus on enjoying your flights rather than dealing with mechanical setbacks.

Overview Of The Generic CDI For Polini Thor 250

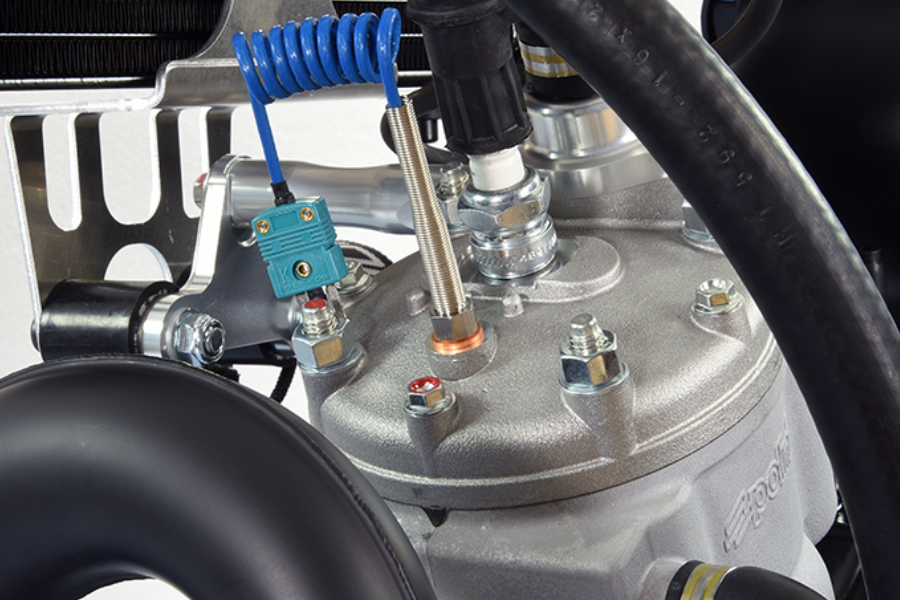

The Polini Thor 250 CDI problem can impact the performance and reliability of your paramotor’s ignition system. The generic CDI (Capacitor Discharge Ignition) serves as a vital part of this system, helping the engine start and operate efficiently. It functions by storing electrical energy in a capacitor and quickly discharging that energy to the ignition coil, resulting in a high-voltage spark necessary for igniting the air-fuel mixture in the engine. The precise timing of this spark is crucial; if it occurs too early or too late, it can lead to engine misfires or prevent the engine from starting altogether.

Understanding how the CDI works is essential for paramotor pilots. A properly functioning CDI ensures smooth engine operation, delivering reliable power during flights. Familiarity with this component can enhance your confidence while flying, enabling you to identify and troubleshoot issues more effectively. This knowledge contributes to a safer and more enjoyable flying experience, allowing you to focus on the thrill of flight rather than potential mechanical problems.

Key Features Of The Polini Thor 250 CDI System:

- Capacitor Discharge Ignition (CDI): The system stores electrical energy in a capacitor and discharges it to the ignition coil to generate a high-voltage spark.

- Engine Timing Control: Precise timing of the ignition spark is crucial for optimal engine performance, preventing misfires or starting issues.

- Compatibility: The CDI is designed to match the specific requirements of the Polini Thor 250 engine, ensuring reliable ignition and operation.

- Cost-Effectiveness: Generic CDIs provide a more affordable alternative to OEM parts, making them accessible for pilots needing replacements.

- Availability: These components are often easily found at local stores or online, facilitating quick replacement when needed.

- User-Friendly Installation: Many generic options are designed for easy installation, allowing pilots with limited mechanical experience to replace them confidently.

- Performance Reliability: A well-functioning CDI is essential for smooth engine operation, delivering consistent power during flights.

- Preventive Maintenance: Regular inspections and cleaning of the CDI system help maintain performance and prolong its lifespan.

- Interchangeability: Some generic CDIs can be interchanged with OEM units, provided they meet the engine’s specifications.

- Community Support: Engaging with fellow pilots can provide insights into the best brands and models for generic CDIs, enhancing decision-making for replacements.

Advantages Of Choosing A Generic CDI For The Polini Thor 250

Opting for a generic CDI Polini Thor 250 offers numerous advantages for paramotor enthusiasts. One significant benefit is cost savings; generic CDIs are generally more affordable than original equipment manufacturer (OEM) parts, making them accessible for pilots who need to replace worn or malfunctioning components without overspending. This is especially advantageous for frequent flyers or hobbyists who wish to maintain their equipment economically.

Another appealing feature of generic CDIs is their widespread availability. These components can often be found at local stores or online retailers, ensuring quick access when replacements are necessary. Many generic options also boast user-friendly installation, making it easier for those with limited mechanical experience to replace parts confidently. However, it’s crucial to be cautious, as not all generic products are created equal. Selecting a reputable brand is essential to avoid performance issues or potential engine damage down the line.

Selecting The Right Generic CDI For Your Polini Thor 250

When choosing the right generic CDI Polini Thor 250, compatibility should be your top priority. Ensure that the CDI meets your engine’s specific requirements, such as voltage and timing settings. An incompatible unit can cause severe performance issues, including misfires or complete engine failure. Carefully reviewing product details and comparing them to your engine’s specifications before making a purchase can prevent these problems.

Quality is another critical consideration. Not all generic CDIs offer the same level of performance as OEM parts. Look for brands with positive feedback from fellow Polini Thor 250 users to guide your decision. While high-quality generic CDIs may come at a slightly higher cost, they can save you money in the long run by reducing the frequency of replacements and maintenance issues. Additionally, consider any warranty or satisfaction guarantees offered with the CDI, as these can provide peace of mind if the product fails early or does not perform as expected.

Typical Problems AssociatedWith The Generic CDI In The Polini Thor 250

Despite their benefits, generic CDIs can encounter common problems that every pilot should be aware of. One common problem is the “no spark” scenario, where the engine does not start because the ignition system is unable to produce a spark. Common causes for this problem include damaged wiring, a faulty ignition coil, or a malfunctioning CDI unit. Experiencing this issue can be frustrating, especially if you have plans to fly.

Misfires are another concern; they occur when the CDI releases the spark at the incorrect moment, leading to uneven engine performance. This can result in a shaky or unstable flight experience. Misfires can stem from poor ignition timing or a weak spark from the CDI. Regular checks on your CDI and ignition components can help identify these issues early, preventing more significant problems from developing.

Intermittent spark is another common problem, where the CDI works sporadically, causing unpredictable engine behavior. This issue often results from loose connections or failing components within the CDI unit. Keeping connections clean and secure can help mitigate this risk. Lastly, poor ignition timing due to a faulty CDI can lead to general engine performance issues, including reduced power output and sluggish throttle response. Being aware of these common issues is crucial for maintaining your paramotor’s functionality.

Preventive Maintenance For The Generic CDI Polini Thor 250

Proper maintenance of your generic CDI Polini Thor 250 is vital for keeping your paramotor in excellent condition. Regular inspections should be part of your maintenance routine, involving checks of wires, cables, and connectors for signs of wear, damage, or corrosion. Identifying these issues early can prevent significant problems in the future, so it’s wise to conduct these checks before each flight.

Using high-quality components for replacements is also essential. Whether you choose OEM or generic parts, ensuring they meet or exceed original specifications will enhance the longevity and performance of your paramotor. While low-quality parts may seem cost-effective initially, they can lead to frequent failures and increased repair needs.

Additionally, keeping the CDI system clean is critical for optimal performance. Dirt, moisture, and corrosion can negatively impact the CDI and related components. After each flight, take a moment to clean the area around the CDI and ensure it remains dry. Storing your paramotor in a clean, dry location also helps protect it from the elements. By following these preventive maintenance tips, you can significantly reduce the risk of CDI-related issues and ensure your generic CDI Polini Thor 250 operates smoothly.

Troubleshooting No-Spark Problems In The Generic CDI Polini Thor 250

Dealing with a no-spark issue in your generic CDI Polini Thor 250 can be frustrating, but a systematic approach can help you identify and resolve the problem. Begin by examining the ignition coil, which plays a critical role in amplifying the voltage from the CDI to generate the spark necessary for starting the engine. A faulty or damaged ignition coil will prevent your engine from starting. Utilize a multimeter to test the coil’s resistance; if the readings fall outside the manufacturer’s specifications, replacing the ignition coil will be essential.

Next, pay attention to the wiring. Damaged or corroded wires can disrupt the electrical flow between the CDI and the spark plug, leading to a no-spark condition. If you find any issues, repair or replace the affected sections to ensure a reliable electrical connection. Regular maintenance of your wiring can significantly reduce the chances of encountering no-spark problems in the future.

Use a multimeter to check for continuity and output voltage. If the CDI unit is malfunctioning, it will need to be replaced with a compatible one. Additionally, don’t overlook the pickup coil, as it sends timing signals to the CDI. If this component is damaged, it can also lead to no-spark situations. Inspect it for wear and ensure that it is functioning properly. By following these troubleshooting steps, you can effectively resolve no-spark issues and ensure that your generic CDI Polini Thor 250 is ready for flight.

Comparing OEM And Generic CDI Units For The Polini Thor 250

When it comes to selecting between OEM (Original Equipment Manufacturer) and generic CDI units for your Polini Thor 250, understanding their differences is crucial. OEM parts are designed specifically for your engine, adhering to strict quality standards and specifications set by the manufacturer. This often results in greater reliability and performance during flights. OEM CDIs are crafted from high-quality materials and undergo extensive testing, ensuring optimal functionality under various conditions.

In contrast, generic CDI units tend to be more cost-effective, making them an attractive choice for budget-conscious pilots. They are usually more affordable than OEM parts and widely available, allowing for quick replacements. However, the quality of generic units can vary significantly. Some may not match the performance or durability of OEM parts, which could lead to issues such as misfires or reduced engine efficiency.

When deciding which option is best for you, consider your flying habits. If you fly frequently or rely on your paramotor for critical tasks, investing in an OEM CDI might be worthwhile. For casual flyers or those looking to save money, a high-quality generic CDI can still provide good performance, as long as you choose wisely. Researching user reviews and opting for reputable brands can help ensure that you select a reliable generic option. Ultimately, your decision will depend on balancing cost, performance, and your specific needs as a pilot.

Real User Experiences: Success And Challenges With The Generic CDI Polini Thor 250

User experiences with the generic CDI Polini Thor 250 can offer valuable insights into its performance and reliability. Many pilots have shared their positive experiences, noting that switching to a generic CDI has enhanced their overall flying experience. Users often report improved engine reliability, easier starts, and smoother operation after installing high-quality generic units. This affordability and availability make it easier for pilots to keep their equipment in top condition without incurring significant costs.

However, challenges do exist, and it’s important to remain aware of potential issues. Some pilots have encountered performance inconsistencies with generic CDIs, including misfires and intermittent spark issues that impact engine reliability. Reports of cheaper generic options failing to withstand the demands of frequent flying have also surfaced. This highlights the importance of choosing a reputable brand when opting for a generic CDI.

Overall, experiences with generic CDIs vary widely. While many pilots find success, others may prefer the reliability of OEM parts. Engaging with fellow pilots in forums or local flying groups can provide a wealth of firsthand accounts and recommendations, helping you make informed decisions for your Polini Thor 250 based on real-world experiences.

Expert Insights: Enhancing Performance With The Generic CDI Polini Thor 250

Experts in paramotoring offer valuable insights for enhancing performance with the generic CDI Polini Thor 250. A primary recommendation is to focus on the installation process. Proper installation is crucial for ensuring optimal performance; ensure that all connections are secure and that the CDI is mounted correctly. A poorly installed CDI can result in electrical issues that negatively impact engine performance.

Regular tuning and maintenance are also essential for maximizing performance. Keeping your paramotor well-tuned can greatly improve its operation, with the CDI playing a key role in this process. Adjusting ignition timing, where applicable, can enhance engine efficiency and responsiveness. Experts suggest referring to your engine’s manual to understand the ideal settings and make necessary adjustments.

Additionally, experts stress the importance of using high-quality fuel and maintaining the overall health of your engine. High-quality fuel can complement the CDI’s performance, ensuring smooth and efficient engine operation. Regularly changing filters and keeping the engine clean can help prevent CDI-related issues.

Lastly, staying informed about product reviews and advancements in CDI technology is beneficial. Engaging with the paramotor community and keeping up with the latest user experiences can provide you with valuable knowledge. By following these expert insights, you can enhance the performance of your generic CDI Polini Thor 250, ensuring a reliable and enjoyable flying experience.

FAQs About Polini Thor 250 CDI Problems

1. What are the common symptoms of a faulty Polini Thor 250 CDI?

Common symptoms include difficulty starting the engine, ignition failures, inconsistent power delivery, and misfires during operation.

2. How can I troubleshoot a no-spark issue?

Check the ignition coil, inspect the wiring for damage or corrosion, test the CDI unit with a multimeter, and examine the pickup coil for proper functioning.

3. Are generic CDIs reliable for the Polini Thor 250?

While many pilots report positive experiences with high-quality generic CDIs, reliability can vary. It’s essential to choose reputable brands and ensure compatibility with your engine.

4. How can I maintain my Polini Thor 250 CDI?

Regularly inspect wiring and connectors for wear, use high-quality components for replacements, and keep the CDI area clean and dry to prevent corrosion.

5. What should I consider when choosing between OEM and generic CDIs?

Consider your budget, flying frequency, and the reliability of the product. OEM parts offer greater reliability, while high-quality generic options can be cost-effective for casual flyers.

Conclusion

Understanding the polini thor 250 cdi problem and its potential problems is essential for maintaining optimal performance and reliability in your paramotor. A well-functioning CDI is critical for ensuring smooth engine operation and enjoyable flying experiences. While generic CDIs can provide cost-effective alternatives to OEM parts, selecting high-quality options and adhering to proper maintenance practices can significantly enhance their performance and longevity.

By being proactive in troubleshooting common issues and familiarizing yourself with the CDI system, you can prevent mechanical setbacks and focus on what truly matters: enjoying the thrill of flight. Engaging with fellow pilots and seeking expert insights can further enhance your knowledge, allowing you to make informed decisions for your paramotor and ultimately improve your flying experience.

Stay in touch for more updates and alerts visit: Sabsastaa